Everyone has different hobbies, so the choices will be different. If you want to have your own style or want to build your own brand, then you can understand our customization process.

First of all, you can first understand the characteristics of several materials and materials commonly used in making sandals.

Sand sole material:

1. Natural leather: The sole is mainly made of cowhide. The sole is made of cowhide. The thickness is 4-6m/m. The leather is finer skin fiber, but it can only be used for about half a year. The price is relatively high. Its advantages are easy to set. Invariable type, fit, good elasticity, can reduce impact and not easy to fatigue, ventilation absorbs wet fluorine, etc., and is easy to process, and the sentence is easy to display beautifully. The only drawback is the heavier.

2.PVC sole: It can be divided into injection PVC bottom and hand-made bottom. It is easy to slip and not wear-resistant. It is not easy to shape by hand. The shape is a lack of beauty and salt. The biggest advantage is that it can be mass-produced.

3. EVA sole: quality is easy to process, not wearable, not resistant to oil.

4. Rubber bottom: heavyweight, not oil resistant, must be thickened on the bonding surface when molding the bottom, easy to shorten when heated. Inconsistent colors.

5. Raw rubber bottom: heavyweight, more responsible, not resistant to oil, not heat resistant. Easy to change color.

6. Wood bottom and cork: lightweight.

7.PU bottom: lightweight and good elasticity.

Upper material:

1. Natural skin: There are many kinds of leather, snakeskin, sheepskin, pigskin, shark skin, deer skin, reptile skin, horse skin, and others.

Generally, the natural skin has good properties such as softness, no abrasion, moisture absorption, moisture absorption, and heat preservation. The only biggest shortcoming is the lack of source, the difficulty of purchase, and the inconsistency of colors, making it difficult to cut, sew and match. In addition, the extension is larger than the average shoe material and the price is high.

2. All kinds of PVC skin: It is the raw material with the highest usage rate of plastic footwear. Its characteristics are large and the color is relatively consistent, and the production quality is easy to control. Its shortcoming is that it is not breathable and does not absorb. Moisture, cold and brittle, easy to deform, less stretch than natural skin, but larger than PU leather, black skin is easy to absorb heat, not high heat. The price is lower.

3. Various P U skins: Between natural skin and PVC skin, it is slightly breathable and hygroscopic, with large production capacity and easy production, but it is not easy to shape and deform. The stretch is small.

4. All kinds of canvas: This kind of shoe material generally needs to be coated with resin, so that the width is reduced when it is attached. Its characteristic is good softness, but it does not absorb moisture, is not breathable, and has a large stretch. The colors are not consistent. The white canvas is easy to turn beige when it is hot. Used for general vulcanized sports shoes.

5. Various tail dragon cloth: This kind of shoe material is widely used in sport’s shoes, light in weight and excellent in softness, heat preservation, slightly airtight, and absorbs wet fluorine.

Inner material:

Microfiber skin: It has excellent wear resistance and excellent cold resistance, air permeability and aging resistance.

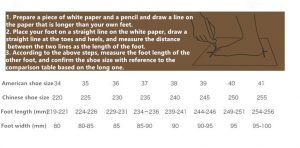

Then you can check out our size chart:

Remarks: Everything is based on real objects

Finally, please understand our customization process.

1. The customer provides pictures, drawings or samples of the required sandals and informs the quantity, size, delivery date, and other requirements.

2. The factory confirms the quantity, delivery date logistics method, invoice and price according to the customer’s requirements.

3. The customer pays the advance payment, our factory arranges the production and communicates with the customer after the first finished product is finished. After the customer confirms the first finished product, our factory arranges the mass production.

4. After the factory completes the production according to the customer’s requirements, it informs the customer to inspect the goods or inspect the goods through pictures and videos. After the inspection is satisfactory, the customer pays the final payment, and our factory arranges the delivery.

If you want to know about our products, you can go to our sandal manufacturer website to find out, if you like, you can place an order directly! We will be happy to help you.